ABOUT US

Atlas Tooling, established in 1996, is an ISO-9001 certified manufacturing company, based in Braeside, which has a large-scale machining and Tool and Die making capacity.

We provide Tool and Die making, service and repair, CNC machining, spark EDM services, CMM Inspection & metrology services, and project management. We particularly specialise in the manufacturing of precision components, jigs and fixtures and press tools and moulds.

Atlas Tooling has had experience in providing services to a wide range of customers representing various industries, including, but not limited to: general engineering, food, transport, marine, medical, mining, security white goods and automotive.

Our professional workforce, with strong engineering backgrounds and rich project management experiences, deeply understands customers’ needs, and provides professional DFM analysis’ and customer-oriented manufacturing solutions, for the best approach to custom parts manufacturing. Our quick turn-over times and professional manufacturing guide helps our customers to save time and cost in product development.

Atlas Tooling also have international partnerships with specialist suppliers in South Korea, Malaysia and China.

Quality Assurance

Focus on service and quality

By developing a long term, close alliance with your business, Atlas Tooling better understands your products and processes. In fast paced, competitive global manufacturing, this is a critical Product Lifecycle Management factor to reduce costs and time to market.

Outstanding service

Driving the technical precision behind every Atlas Tooling project is the company’s culture of outstanding customer service. Atlas Tooling delivers the highest quality in its jigs, moulds, tools, and also provides full technical support through customer tailored data and document controls.

Global quality

A dedicated quality control system, which can be integrated with your quality program, is part of the collaborative alliance with your business, and assures the precision of all work

Our services

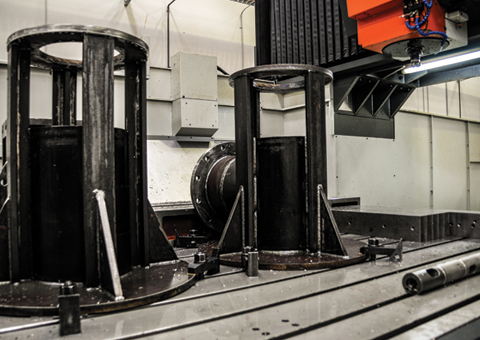

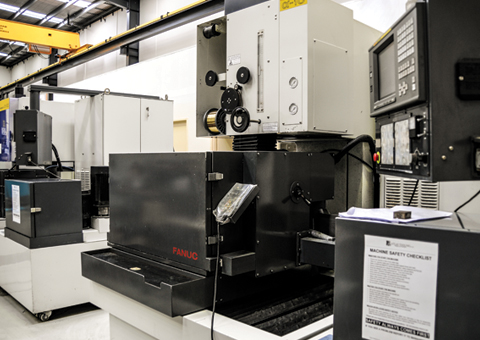

CNC MILLING 3 & 4 AXIS MACHINING

Our CNC Milling section is currently equipped with MAZAK with 4th Axis, Okuma VMC 3 axis , 3 VTEK VMC machines with 4th Axis (Rotary) capabilities. Maximum Table size is 3200x 2300 x 900mm with horizontal attachment and all machines have a 40 tool AT.

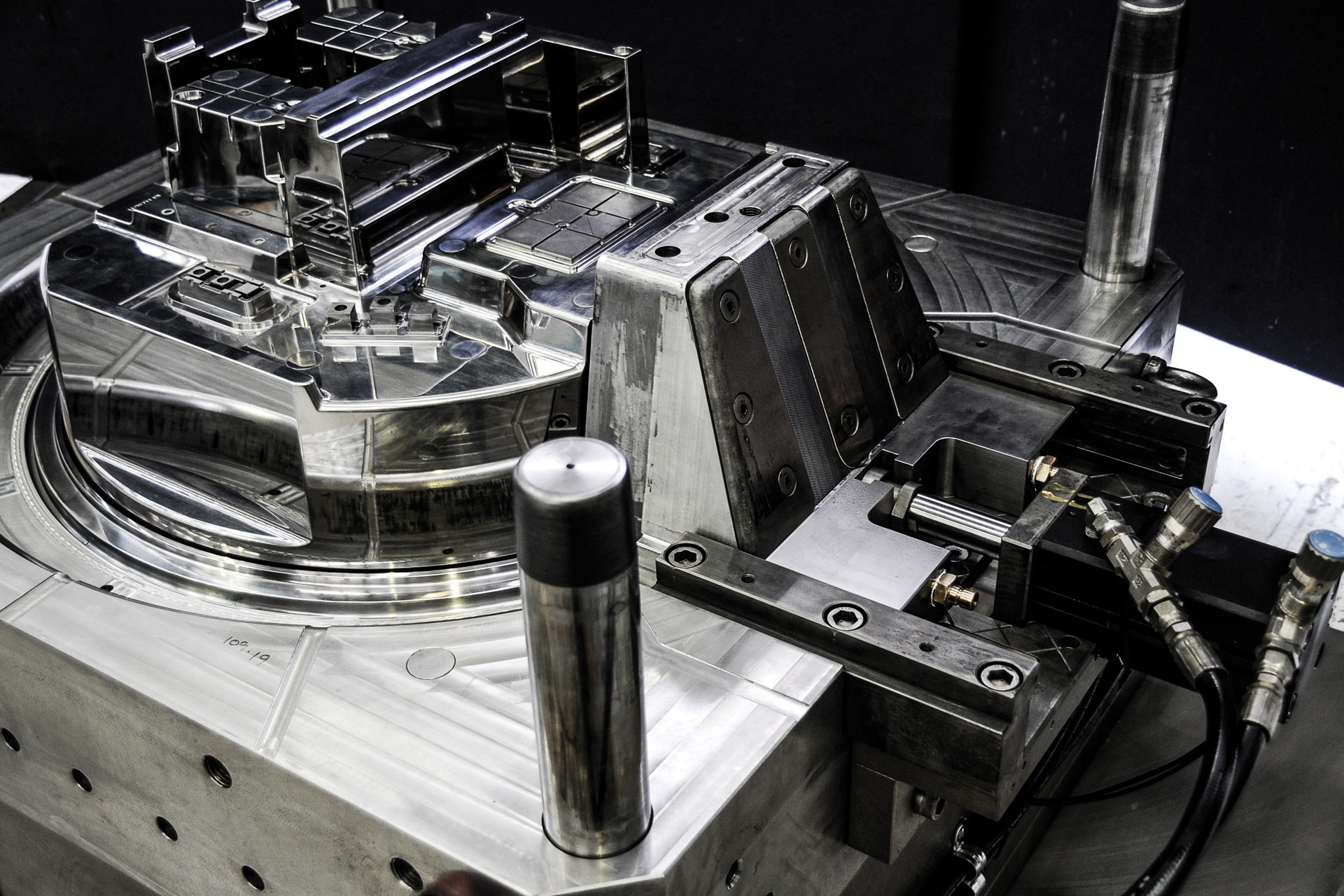

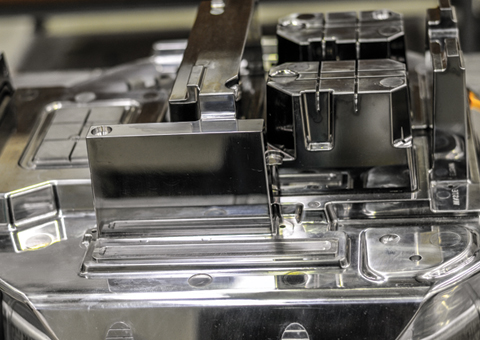

INJECTION MOULDS AND DIES

Get your products to market faster with Atlas Tooling injection moulds and dies. Atlas Tooling precision made moulds and dies produce profit for customers across Australasia.

SERVICE AND REPAIR

Reduce costs with Atlas Tooling contract service and repair facilities to maintain your moulds, dies, jigs, fixtures and special purpose machines in peak operating condition to save your business time and money.

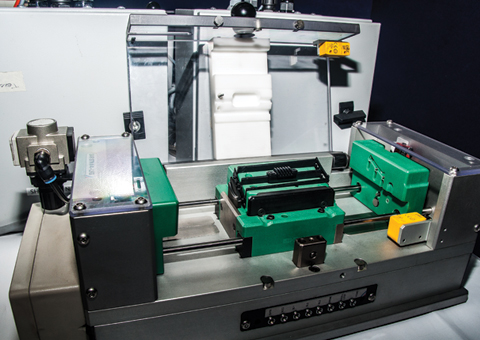

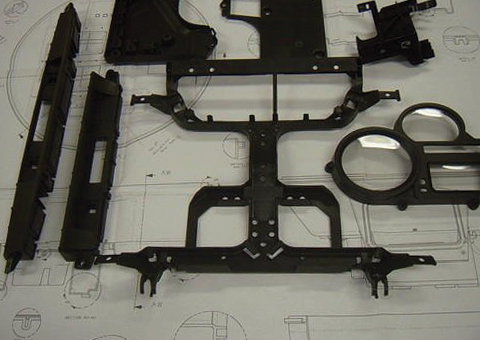

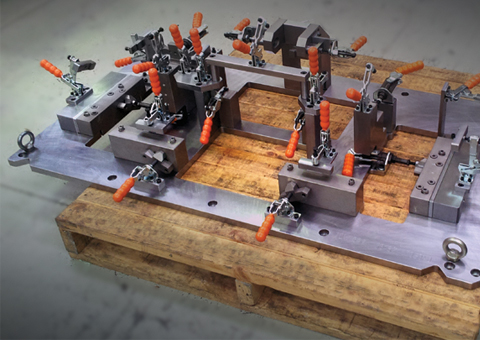

JIGS AND FIXTURES

Using the latest cad / cam software, CNC and EDM techniques from concept to final design and manufacturing, the Atlas Tooling team delivers innovative design solutions that save you time and money.

CUSTOM MACHINING SOLUTIONS

Atlas Tooling does custom machining using the latest CNC and EDM software and techniques. With its state of the art technology, the Atlas Tooling team delivers innovative custom machining solutions for manufacturing industry that save you time and money.

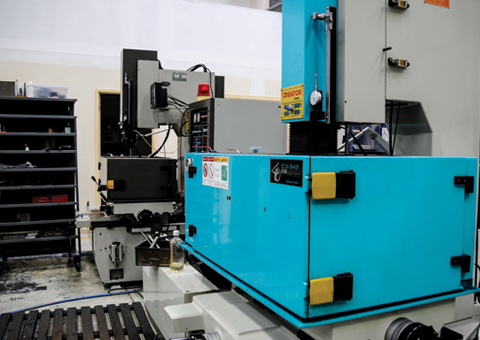

SPARK EDM MACHINING

We are equipped with 2 spark EDM machines and 2 wire EDM machines. Our CNC wire EDM is capable of cutting up to 300mm height.

PROJECT MANAGEMENT

Our professional project management team, with strong engineering backgrounds and rich project management experiences deeply understand customers’ needs, provide professional DFM analysis and customer-oriented manufacturing solutions, for the best approach of custom parts manufacturing.

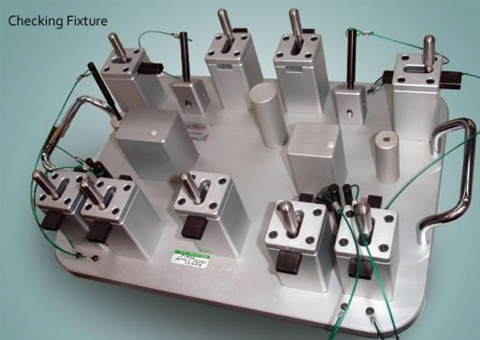

CMM INSPECTION & METROLOGY SOLUTIONS

Atlas Tooling provides independent contracting of dimensional metrology and CMM Inspection services to industry. Our CMM equipment located in a 20°C temperature controlled environment. We utilize the very latest in Metrology technology.

MACHINE CAPACITY

| Machine | Capacity |

|---|---|

| High speed 4 axis CNC Mill - Mazak | 550 x 1300 |

| CNC Mill - Okuma | 600 x 1300 |

| CNC Mill - Sunmill | 1500 x 750 x 700 |

| CNC Mill - VTEC with horizontal head attachment. Can machine angle in 5 degree increments |

3100 x 2200 x 900 |

| CNC Mill - VTEC | 2100 x 1600 x 800 |

| CNC wire cutting - Fanuc | 350 x 300 |

| CNC wire cutting - Fanuc | 400 x 500 |

| EDM - Creator | 600 x 500 |

| EDM - Creator | 800 x 600 |

| CNC lathe | Max turn dia 400 x 1040 mm long |

| Surface grinding | 1000 x 600 |

| CMM - Cordax | 1100 x 800 |

| Over Head Crane | 6.3T |

CAD/CAM Software

Unigraphics NX

MasterCAM

WANT TO KNOW MORE ABOUT OUR COMPANY? CURIOUS WHAT ELSE WE DO?

TECHNICAL PRECISION INCREASES PRODUCTIVITY

To compete in the demanding international market, Atlas Tooling forms close, long term collaborative alliances with its customers. We bring, to these alliances, key assets of skilled and experienced tradespeople, and state of the art equipment.

Design work is completed in-house by the professional Atlas Tooling team using the latest three dimensional computer aided design software, including UG NX and MasterCAM. Special emphasis is placed on mould flow, warp and cooling characteristics, part fit and the production process to ensure customers maximise productivity with Atlas Tooling moulds.

Our facility is equipped to handle tools up to 6.3 tonnes. Facilities include Computer Numerical Control (CNC) Milling, Lathe and Wire Cutters, Electrical Discharge Machines, as well as all conventional machines, such as milling, grinding and turning machines. Atlas Tooling has also had partnerships with specialist suppliers in South Korea, Malaysia and China.

Using these Australian and international facilities, the Atlas Tooling team offers the most comprehensive range of services, including:

- Product design and feasibility analysis

- Prototype development and testing

- Tool design and development

- Design and manufacture of injection moulds

- Design and manufacture of press tools

- Design and manufacture of extrusion dies

- Design and manufacture of special purpose machines

- Design and manufacture of jigs and fixtures

- Custom machining and contract manufacturing

- Tool trialling and commissioning

- Project management of small and large tool applications

- Independent contracting of dimensional metrology and CMM Inspection services